PRODUCTS

Good Design.

Great Beer!

We have two options for bottling your brews! And fantastic labelling units too! Take a peek below to see how our products could improve your products and give you ultimate control of your bottle filling and capping!

ACOS FILLER PRODUCTS

The Acos product range consists of:

- AF250 FILLER

- AF250 SEAL KIT

- AF250 BRITE TANK CONNECTOR KIT

- AF500 FILLER

- ACOS LABELLING MACHINE (ROUND BOTTLE)

- ACOS LABELLING MACHINE (SQUARE BOTTLE)

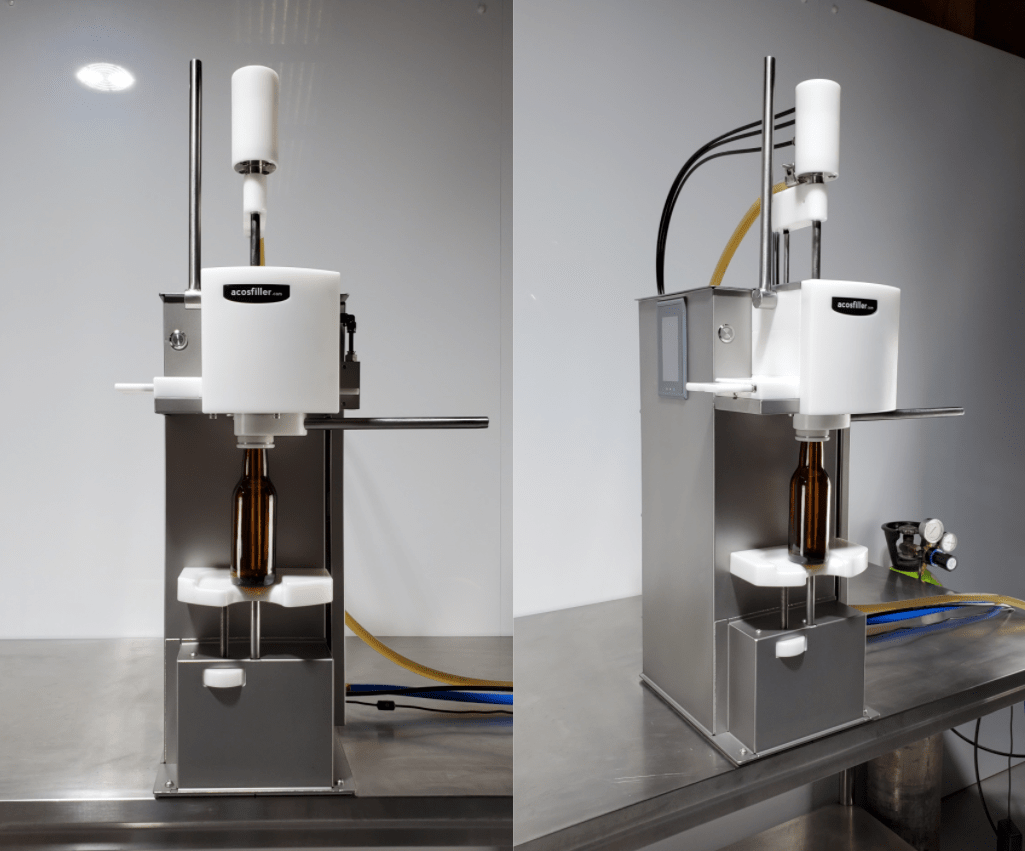

AF250 FILLER

- A5250 Full Spec Sheet - Click Here

- Fast filling speed. Can process up to 250 bottles an hour, with one operator.

- Designed to ensure low oxygen levels in the bottle. Includes patented "FreshCraft™" technology for low pick up oxygen levels.

- "Production Mode" filling and capping results in less than 40 parts per billion (ppb) of pick up oxygen level in bottle.

- "Competition Mode" results in near zero oxygen levels (2ppb), which can be used for brewing competitions for those brewers with medal aspirations.

- Keg or brite tank compatible (requires brite tank connector kit).

- No overhead filling tank required. Fluids piped or tubed in.

- Sustainable — given footprint, mechanics of operation (versus current industry filling solutions).

- Filling mechanism results in a very accurate fill and reduces product wastage. LED controlled.

- Fills from the bottom and controls the fill rate. This gives fast filling, especially when compared to traditional filling solutions.

- Pressure and fill speed is controlled during filling.

- Capping is done under pressure.

- Capping on the foam is also controlled.

- Can accommodate various bottle sizes.

- 26mm and 29mm Crown Cap compatible machines available

- Bottle size changes can be carried out quickly (in one to two minutes).

- Easy to clean and maintain. Food grade standard.

- Protected Intellectual property. Includes patented and patent pending technology.

- Control your own Filling and Capping functions.

- Requires air compressor to operate (not supplied).

AF250 SEAL KIT

- Replacement seal kit for AF250.

- We recommend that seals are replaced every 6 months to ensure that this machine operates efficiently.

AF250 BRITE TANK CONNECTOR KIT

- Kit for easy connection of AF250 machine to Brite Tank to allow seamless filling and capping.

- Kit comprises of 5 meter transparent and food grade hose, together with Brite Tank coupling with purge valve.

AF500 FILLER

- Fast filling speed. Can process over 500 bottles an hour, dependent upon filler head configuration specs.

- Designed to ensure low oxygen levels in the bottle. Includes patented "FreshCraft™" technology for low pick up oxygen levels.

- "Production Mode" filling and capping results in less than 40 parts per billion (ppb) of pick up oxygen level in bottle.

- No overhead filling tank required. Fluids piped or tubed in. Keg or brite tank compatible.

- Fully automated.

- Sustainable - given footprint, mechanics of operation (versus current industry filling solutions)

- Filling mechanism results in a very accurate fill and reduces product wastage.

- Fills from the bottom and controls the fill rate. This gives fast filling, especially when compared to traditional filling solutions for carbonated liquids.

- Pressure and fill speed is controlled during filling.

- Capping is done under pressure.

- Capping on the foam is also controlled.

- Bottle and PET compatible.

- Crown cap compatible

- Bottle size changes can be carried out quickly (in one to two minutes).

- Easy to clean and maintain. Food grade standard.

- Protected Intellectual property. Includes patented and patent pending technology.

ACOS LABELLING MACHINE (ROUND BOTTLE)

- Simple and Easy to use.

- 100% manual operation.

- Labels are applied quickly and effortlessly.

- Applies labels on a uniform and consistent basis to every bottle.

- Can accommodate bottle sizes from 330ml to 1.5 litres.

- NOTE: This machine is for round bottles.

- Requires no power or electricity to operate.

- Operated by one person

- Easy to clean.

- Cost effective labelling machine.

ACOS LABELLING MACHINE (SQUARE BOTTLE)

- Simple and Easy to use.

- 100% manual operation.

- Labels are applied quickly and effortlessly.

- Applies labels on a uniform and consistent basis to every bottle.

- Can accommodate bottle sizes from 330ml to 1.5 litres.

- Requires no power or electricity to operate.

- Operated by one person.

- Easy to clean.

- Cost effective labelling machine.

- NOTE: This machine is for square bottles.

LOW OXYGEN LEVELS

Our filling and capping machines ensure low oxygen pick up in the bottle. Low Oxygen levels are critical for great beer!

We have developed our patented filling technology, called Freshcraft that ensures low pick up oxygen levels reside in a filled and capped bottle. This patented technology is built into all Acos Filler machines.

Low oxygen levels are critical to ensure:

- Original beer flavor longevity; and

- The product has a long and stable shelf life.

Based upon extensive testing we are able to guarantee pick up oxygen levels are less than 40 parts per billion (ppb) in the Acos Filler filling and capping machine's "Production Mode". The AF250 machine also includes a filling and capping "Competition Mode" that results in near zero oxygen levels (circa 2 ppb), which can be used for beer competitions for those brewers with medal aspirations.